Aluminum Alloy Casting Trivalent Chromium Passivator Concentrated Liquid AL-100

-

Podkreślić

aluminum anodizing additives

,anodizing chemical agent

-

TypSkoncentrowany płyn

-

FunkcjaAntykorozja

-

Używaćstopy aluminium i odlewy aluminiowe

-

Miejsce pochodzeniaChiny

-

Nazwa handlowaFENGFAN

-

Numer modeluAL-100

-

Minimalne zamówienieZbywalny

-

Cenanegocjowalne

-

Szczegóły pakowaniaStandardowe opakowanie eksportowe

-

Czas dostawy15-25 dni roboczych

-

Zasady płatnościL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Możliwość Supply200000pcs/dzień

Aluminum Alloy Casting Trivalent Chromium Passivator Concentrated Liquid AL-100

AL-100

Aluminum alloy trivalent chromium passivator

Concentrated liquid for trivalent chromium passivation of aluminum

Its anti-corrosion performance is superior to six valence chromium passivation.

It is also be used for aluminum alloy and aluminum casting.

It can be used for the pretreatment of paint, powder coating and sizing processing.

It is easy to operate for immersion, spray, hand wipe.

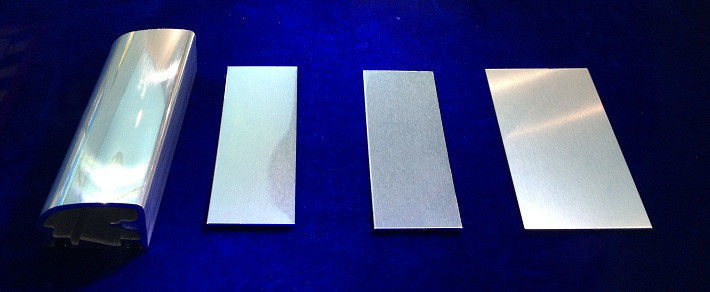

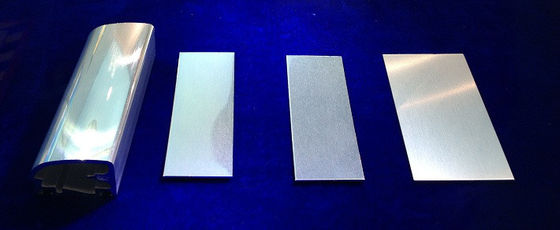

It formed a transparent, light colored coating.

Low contact resistance, less than 0.8 mOhm/cm2.

It can be resistant to the high temperature of 100 centigrade degree without detracting from its corrosion resistance ability

Protect the environment, non-toxic, simple operation and wastewater treatment.

meet or exceed the MIL-DTL-81706 and MIL5541 corrosion standard (according to ASTMB-117 and DIN 50021 SS neutral salt spray test standard, more than 336 hours to appear white rust)

1. TECHNICAL PROCESS

Standard immersion technology

Aluminum alloy (silicon content <1%): alkaline degreasing → alkali erosion → descaling → immerse AL-100

Aluminum alloy (silicon content >1%): alkaline degreasing → cleaning → immerse AL-100

Standard spray process

Acidic degreasing → spray AL-100